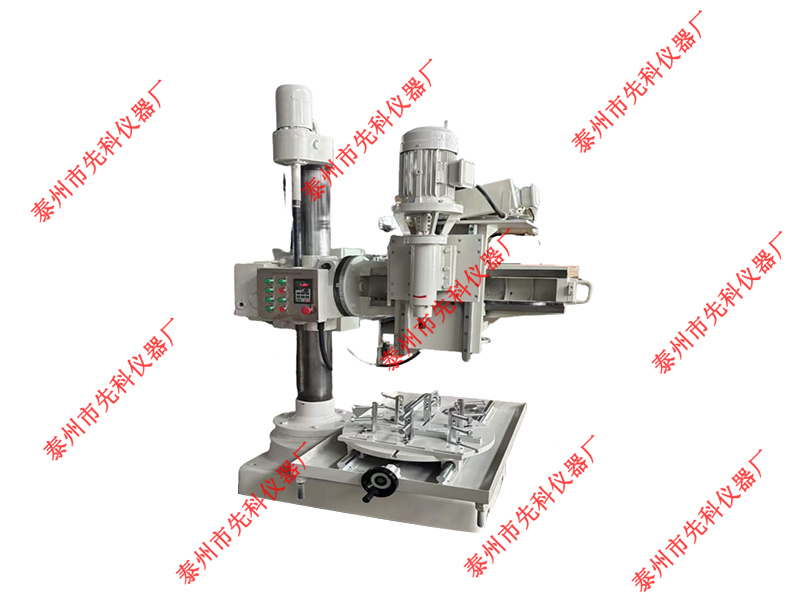

SCM200A Program-controlled Grinding Machine

Product Description: The SCM200A CNC double-sided polishing machine is a new generation of automatic CNC polishing machine newly developed by our factory. It is essential equipment for making standard samples for mechanical testing of various non-metallic solids such as rocks, minerals, and concrete. This machine adopts user-friendly tablet computer input and monitors the grinding process throughout, making sample grinding simpler. Input parameters are set on the display screen, and the system will start working and return after reaching the set size. This machine consists of a machine base, a grinding power head stepping motor system, PLC, LCD screen, electronic components, a system control device compensation coefficient, and a measurement system. One-button operation, automatic completion. Technical Parameters: 1. Workbench motor power: 0.75KW Speed 720rpm 2. Grinding power head power: 1.1KW × 2 units Speed 2750rpm 3. Servo motor and drive 4. Transmission system: Ball screw and ball guide rail. 5. Digital protection system. 6. Panel control: Touch screen 7. Electrical control: PLC 8. Grinding wheel specifications: φ200 × φ19 × 40mm × 2; 9. Polishable sample specifications: 25mm-150mm, (normal factory configuration grinds 50~150mm fixture) a: Cube: 50×50×50~150×150×150mm b: Cylinder: 7~150mm 10. Automatic grinding feed: Input on the display screen. 11. Automatic grinding feed: 0.04~0.2mm (adjustable); 12. Smoothness: (according to mechanical processing roughness standard): Ra3.2; 13. Standard precision flatness: The error within the range of 100 test pieces ≤0.04mm, verticality ≤0.1mm; 14. Equipped with motor phase loss, overcurrent, and overload automatic system protection 15. Cooling device: Tap water cooling.

Keywords:

Detailed description

Product Description:

The SCM200A CNC double-sided polishing machine is a new generation of automatic CNC polishing machine newly developed by our factory. It is essential equipment for making standard samples for mechanical testing of various non-metallic solids such as rocks, minerals, and concrete. This machine adopts user-friendly tablet computer input and monitors the grinding process throughout, making sample grinding simpler. Parameters are input on the display screen, and the system will start working and return after reaching the set size. This machine consists of a machine base, a grinding power head stepping motor system, PLC, LCD screen, electronic components, a system control device with a compensation coefficient, and a measurement system. It features one-button operation and automatic completion.

Technical Parameters:

1. Worktable motor power: 0.75KW Speed 720rpm

2. Grinding power head power: 1.1KW × 2 units Speed 2750rpm

3. Servo motor and driver

4. Transmission system: Ball screw and ball guide.

5. Digital protection system.

6. Panel control: Touch screen

7. Electrical control: PLC

8. Grinding wheel specifications: ¢200 × ¢19 × 40mm × 2 pcs;

9. Polishable sample specifications: 25mm-150mm, (standard factory configuration grinds 50~150mm fixtures)

a: Cubes: 50×50×50~150×150×150mm

b: Cylinders: 7~150mm

10. Automatic grinding feed rate: Input on the display screen.

11. Automatic grinding feed rate: 0.04~0.2mm (adjustable);

12. Smoothness: (according to mechanical processing roughness standard): Ra3.2;

13. Standard precision flatness: Within the range of 100 test pieces, the error ≤0.04mm, perpendicularity ≤0.1mm;

14. Equipped with motor phase loss, overcurrent, and overload automatic system protection

15. Cooling device: Tap water cooling.

Related Products

Inquiry Message

We will contact you within one working day. Please pay attention to your email.