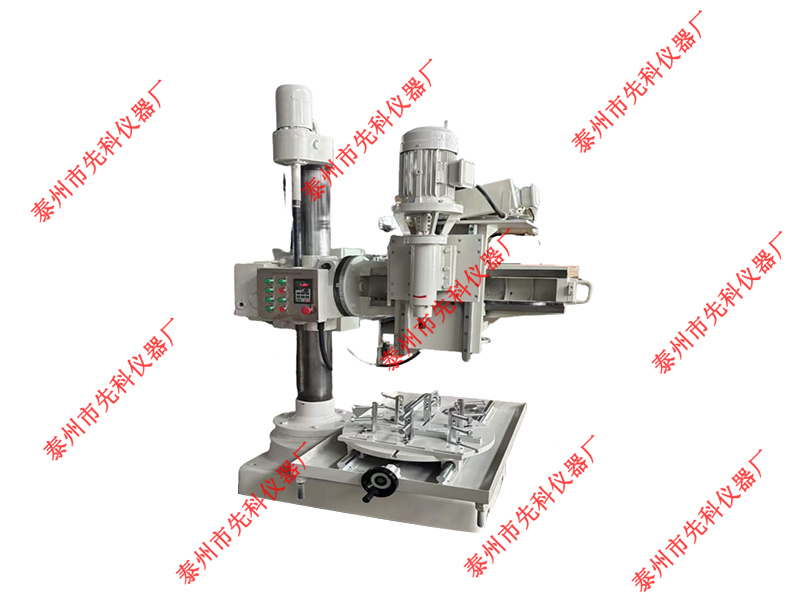

SC-ZQM Rock Core Drilling and Grinding Machine

Keywords:

Category:

Detailed description

I. Overview

This coring machine is mainly used for various rocks, processed stones, etc., to core a certain part of them. It can also be widely used in laboratories of petroleum, geology, coal, metallurgy, construction, and transportation departments to collect experimental core samples. It is essential equipment for laboratory sampling. This equipment has the advantages of beautiful appearance, durability, high strength, low noise, and convenient operation.

II. Main Technical Parameters

Maximum coring depth: ≤300mm.

Core diameter: Φ25-Φ200mm

Cutting diamond blade: Ø300

Polishing diamond wheel: Ø200

Vertical travel: 800mm

Horizontal travel: 300mm

Chuck diameter: Φ600mm

Main motor power: 3KW

Lifting motor: DC36v/250w

Working time: Continuous

III. Structural Principle

This machine is mainly composed of a base, column, lifting arm, motor, control part, lifting reduction mechanism, worktable longitudinal and transverse (cross slide), chuck, and cooling system. The base, column, lifting arm, and motor have high inherent strength and are very stable when drilling large-diameter rock cores. The main spindle rotation of this machine is driven by the main motor through a V-belt.

1. Lifting Arm

The lifting motor is installed at the top of the column, and the power on the reducer is transmitted to the screw through a worm gear reducer, causing the screw to move forward and backward, driving the rocker arm to rise and fall. This machine is driven by a motor through a V-belt.

According to the hardness of the coring drill bit and the specimen, the appropriate lifting speed is selected for automatic drilling.

The lifting arm diagram is shown below:

2. Worktable Longitudinal and Transverse (Cross Slide) Movement

The worktable longitudinal device is designed with a screw and nut mechanism on the base, and the worktable is installed with a slide plate and nut seat. By turning the handwheel, the screw is driven, causing the worktable slide plate to move longitudinally, with a longitudinal travel of 800mm.

The worktable transverse device is designed with a screw and nut mechanism on the slide plate, and the worktable is installed with a nut seat. By turning the handwheel, the screw is driven, causing the worktable to move transversely, with a transverse travel of 300mm.

The worktable longitudinal and transverse device can move longitudinally and transversely to meet the requirements of the workpiece and sample coring position.

3. Fixture Chuck

A standard Φ600mm chuck is installed on the transverse device slide plate to fix workpieces or samples of different sizes with claws.

4. Cooling System

The cooling water for this machine is tap water. The power supply of this machine uses three-phase 380V. The ground wire should be connected to the grounding stake screw of the fixed equipment. A return water tank is designed around the equipment base, and the cooling water finally returns to the cooling water tank through the return water tank and a filter device.

Related Products

Inquiry Message

We will contact you within one working day. Please pay attention to your email.