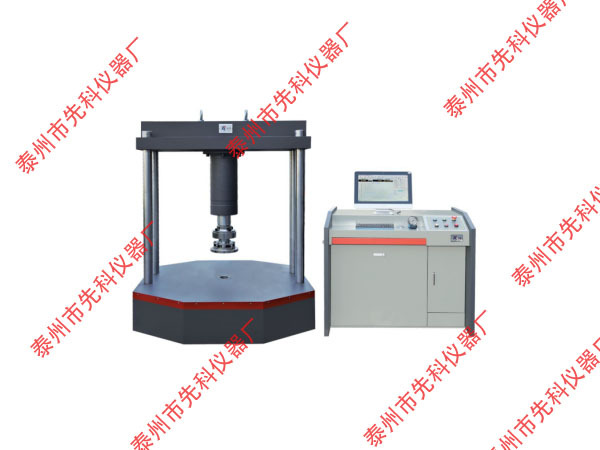

DYJ-1000S Computerized Fully Automatic Manhole Cover Pressure Testing Machine

Keywords:

Category:

Detailed description

I. Product Introduction

The DYJ-1000S computer-controlled automatic manhole cover pressure testing machine is a high-precision material testing equipment driven by a hydraulic power source, utilizing electro-hydraulic servo control technology, and computer data acquisition and processing. It can achieve closed-loop control and automatic detection. It consists of four parts: the main testing machine, oil source (hydraulic power source), measurement and control system, and testing fixtures. The maximum test force is 1000kN, and the accuracy grade of the testing machine is 1st grade.

The DYJ-1000S computer-controlled automatic manhole cover pressure testing machine is used for bearing capacity (residual deformation and test load) tests of manhole covers made of various materials. It can achieve closed-loop control such as equal-rate loading and equal-rate deformation, and can automatically obtain the technical indicators of the test pieces.

This testing machine and its accessories comply with the following standard requirements:

GB/T23858-2009 "Manhole Covers"

GB/T26537-2011 "Steel Fiber Reinforced Concrete Manhole Covers"

CJ/T211-2005 "Polymer Matrix Composite Manhole Covers"

CJ/T121—2000 "Recycled Resin Composite Manhole Covers"

CJ/T3012 "Cast Iron Manhole Covers"

CJ/T511-2017 "Cast Iron Manhole Covers"

GB/T2611 "General Technical Requirements for Testing Machines"

GB/T16826 "Electro-hydraulic Servo Universal Testing Machine"

II. Product Parameters

Maximum Test Force: 1000KN;

Accuracy Class: 1st grade;

Indicated Value Relative Error: ±1%;

Effective Measurement Range: 1%-100%F·S (full range, no sub-ranges);

Deformation Indicated Value Relative Error: ±1%;

Deformation Measurement Resolution: 0.001mm;

Maximum Compression Surface Spacing: 300 mm;

Effective Distance Between Two Columns: 1200mm;

Piston Stroke: 300 mm;

Maximum Piston Movement Speed: 80 mm/min;

Upper Platen Size: Φ250 mm;

Lower Platen Size: Φ356 mm;

Main Machine Dimensions: 1450 mm × 1250 mm × 1800 mm;

Main Machine Packaging Dimensions: 1660 mm × 1340 mm × 2000 mm

Oil Source Cabinet Dimensions: 1100mm × 735 mm × 900 mm;

Oil Source Cabinet Packaging Dimensions: 1330mm × 1020 mm × 1350 mm;

Overall Machine Power: 1.1KW;

Oil Source Cabinet Weight: 450 kg;

Main Machine Weight: 3000 kg;

Related Products

Inquiry Message

We will contact you within one working day. Please pay attention to your email.