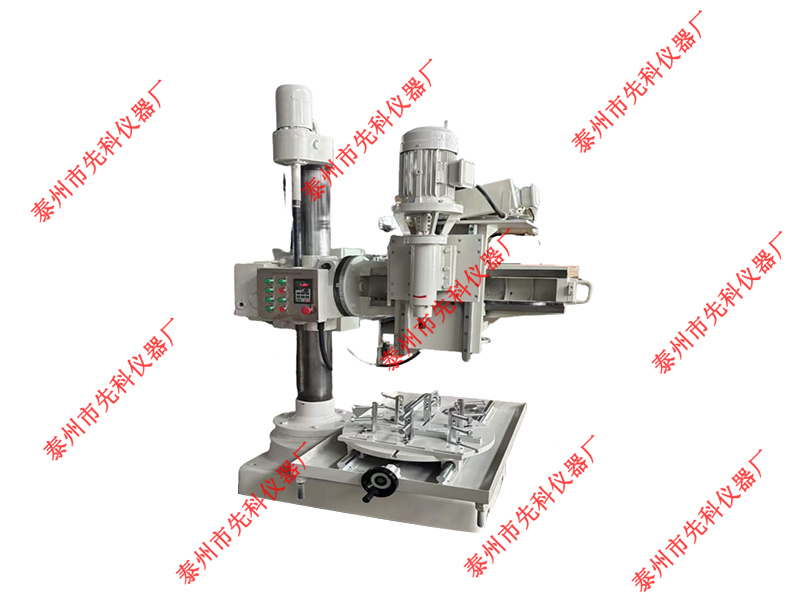

SCM200E double-sided planer

Product Description: The SCM200E automatic horizontal grinding machine uses a light rod horizontal walking method to drive the worktable forward and backward. It is an essential main equipment for making standard samples for mechanical testing of various rock and mineral stones, concrete and other non-metallic solids. This machine works with the core drill and stone cutting machine produced by our factory to process the high-precision cubic or cylindrical test specimens you need. It is widely used in colleges and universities, water conservancy and hydropower, geology and mineral resources, transportation, and construction departments. The whole machine shell is made of stainless steel, beautiful, generous, easy to operate, automatic feeding, and stable performance. Technical parameters: 1. Worktable

Keywords:

Detailed description

Product Description:

The SCM200E automatic horizontal grinding machine uses a horizontal light bar movement to drive the workbench forward and backward. It is an essential main equipment for producing standard samples for mechanical testing of various non-metallic solids such as rocks, minerals, and concrete. This machine works in conjunction with coring machines and stone cutting machines produced by our factory to process high-precision cubic or cylindrical test specimens as required. It is widely used in colleges and universities, water conservancy and hydropower, geology and mineral resources, transportation, construction, and other departments. The entire machine casing is made of stainless steel, which is beautiful, elegant, easy to operate, automatically feeds, and has stable performance.

Technical Parameters:

1. Workbench motor power: 0.75KW;

2. Grinding power head power: Y80 -4 1.1KW×2 units, 2800 revolutions/minute;

3. Working mode: Simultaneous parallel grinding of both end faces

4. Operation method: Automatic or manual grinding

5. Automatic grinding feed amount: 0.04~0.17mm (adjustable);

6. Grinding range: Cube: 40×40×40-150×150×150mm;

Cylinder: Φ50-Φ150 (3-6 core samples can be ground simultaneously);

7. Surface finish: (according to mechanical processing roughness standard): Ra3.2;

8. Standard accuracy flatness: within 50 ±0.05mm, perpendicularity ≤0.1mm;

9. Grinding wheel specifications: ¢200×¢19×40mm;

10. Cooling device: Connect to tap water for cooling; if liquid nitrogen cooling is required, please specify when ordering

11. Overall dimensions: Length 1450×Width 1400×Height 1200mm

12. Weight: 600kg,

Related Products

Inquiry Message

We will contact you within one working day. Please pay attention to your email.