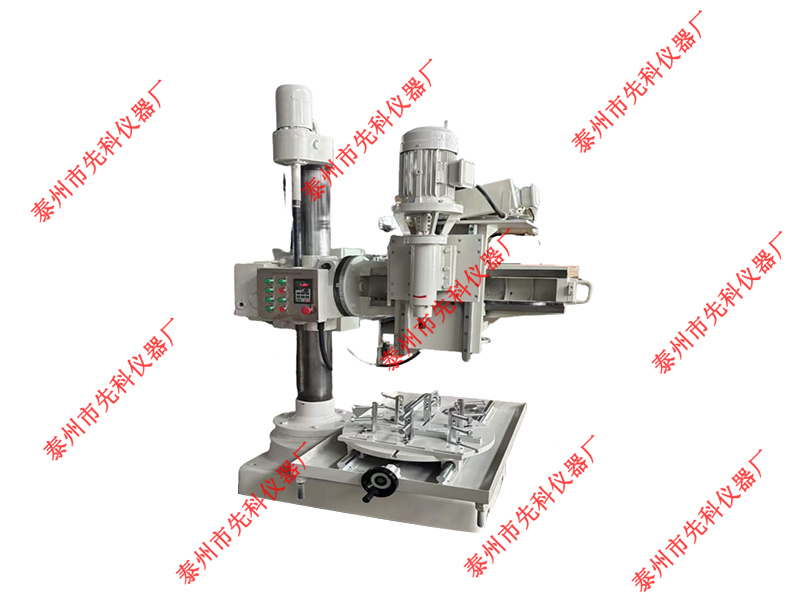

SCM200 double-sided planer

Used for planar grinding of both ends of cut specimens to produce high-precision specimens. This product strictly implements the industry standard of "Highway Engineering Rock Test Regulations" (JTGE41-2005). The machine is equipped with two ¢200 diamond grinding wheels on the power heads. The specimen is installed on the worktable and reciprocates automatically during operation. The grinding head can advance automatically or manually, and the automatic feed speed is adjustable. 1. Grinding wheel specifications: ¢200×¢32×40mm 2. Grinding range: Cube: 50×50×50mm----150×150×150mm; Cylinder: 50--150mm 3. Grinding motion

Keywords:

Detailed description

Used for polishing both ends of cut specimens to create high-precision specimens. This product strictly adheres to the industry standard of the "Highway Engineering Rock Test Regulations" (JTG E41-2005).

The machine's two power grinding heads are equipped with ¢200 diamond grinding wheels. The specimen is mounted on the worktable and automatically reciprocates during operation. The grinding head can advance automatically or manually, and the automatic feed speed is adjustable.

1. Grinding wheel specifications: ¢200×¢32×40mm

2. Grinding range: Cube: 50×50×50mm----150×150×150mm; Cylinder: 50--150mm

3. Grinding power head power: 1.1KW×2, speed 2800rpm; Worktable motor power: 0.55KW, speed 1450rpm

4. Specimen precision: Flatness: Tolerance ±0.05mm within 50mm range; Smoothness: (According to mechanical machining roughness standard) Ra3.2

5. Automatic grinding feed: 0.04~0.12mm adjustable

6. Cooling device: Tap water cooling

7. External dimensions: Length 1360×Width 1100×Height 1200mm (subject to actual dimensions)

8. Weight: 600kg

Note: The above models can be customized with stainless steel casings. The actual product may differ from the image; the physical product shall prevail!

Related Products

Inquiry Message

We will contact you within one working day. Please pay attention to your email.