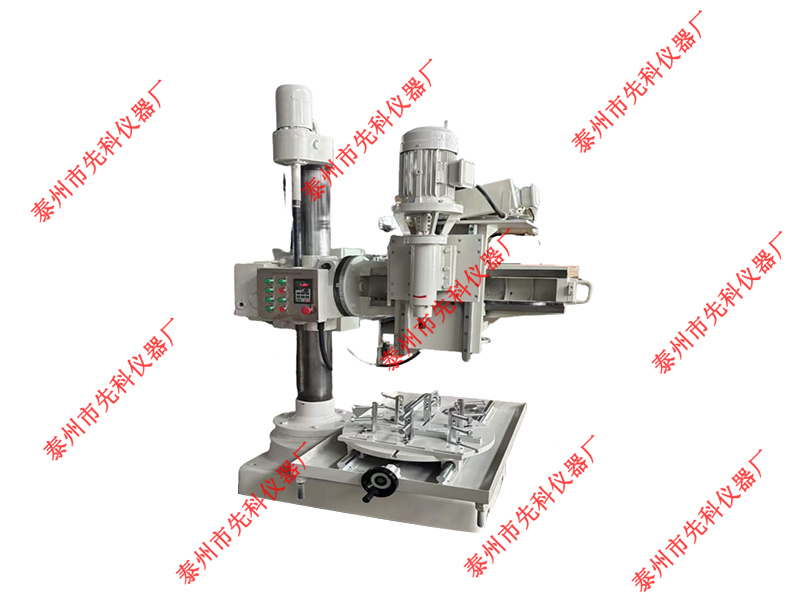

YHDS-100 Rock Multifunctional Thermal Conductivity Tester

Keywords:

Detailed description

I. Overview

The YHDS-100 Multi-functional Rock Thermal Conductivity Tester uses the transient plane source method, based on TPS transient plane source technology, with a Hot Disk probe. It is specifically applied to measure thermal conductivity, thermal diffusivity (thermal diffusion coefficient), specific heat capacity, thermal effusivity, and thermal resistance of anisotropic materials such as geotechnical materials, rocks, polymers, concrete, composite panels, paper honeycomb panels, and other solids, powders, liquids, pastes, coatings, films, thermal insulation materials, and adiabatic materials. It is important equipment for universities and testing institutions.

II. Conformance: Equipment Reference Standards:

1. DZ/T0276.14-2015 Geological and Mineral Industry Standard of the People's Republic of China, Physical and Mechanical Properties Test Procedures for Rocks, Part 14: Rock Thermal Conductivity Test.

2. ISO22007-2-2008 Test Method for Thermal Conductivity and Thermal Diffusivity;

3. GB/T 32064-2015 Transient Plane Source Test Method for Thermal Conductivity and Thermal Diffusivity of Building Materials.

III. Advantages of the instrument:

(1) Directly measures heat propagation, saving a lot of time;

(2) Not affected by contact thermal resistance like static methods;

(3) No special sample preparation is required; for solid materials, only a relatively flat sample surface is needed. Different types of materials adopt different test schemes and mathematical calculation models, offering advantages such as fast measurement speed, wide applicability, and successful avoidance of natural convection effects during the experiment. It has a wide range of actual testable materials, a broad thermal conductivity range, simple sample preparation, and fast test speed, making it a relatively popular test method currently.

IV. Main technical parameters:

1. Thermal conductivity measurement range: 0.001~600 w/(m.k), resolution 0.00015 w/(m.k);

2. Thermal diffusivity (thermal diffusion coefficient) range: 0.15~120 m2/s;

3. Thermal effusivity range: 0.1~30 w/(m2.k);

4. Specific heat capacity range: 0.1~5 kJ/(kg.℃);

5. Thermal resistance range: 0.5~0.000005 mm2.k/w;

6. Temperature measurement accuracy: ≤0.001℃;

7. Relative measurement error: ≤3%;

8. Repeatability error: ≤ 3%;

9. Test time: 1~120 seconds.

10. Probe heating material: Nickel metal; Thickness: 0.01mm, Heating wire width: 0.35±0.03mm;

11. Probe diameter; Standard configuration: Diameter Φ15mm or Φ7.5mm. Optional probe diameters available upon customer request: Φ30mm, Φ15mm, Φ7.5mm, Φ4mm, or simultaneous configuration.

12. Test temperature: Room temperature (standard configuration), Variable temperature: -50℃~150℃ (optional)

12. Power: 0-20w;

13. Maximum voltage: 20V;

14. Maximum current: 1A;

15. Resistance: Around 15Ω, subject to the resistance value marked on the probe;

16. Protective layer material: Polyimide film (Kapton); Single layer thickness: 0.06mm;

17. Probe diameter: Φ30mm, Φ15mm, Φ7.5mm.

18. Test sample requirements:

a. Solid block, round, square, or irregular samples; no special preparation is required, only a relatively flat sample surface. Equipped with a dedicated sample clamping device.

b. No special requirements for powdered, pasty, or liquid substances. Equipped with a dedicated sample test box.

c. For testing thin materials (thickness 0.01~1mm), specialized test schemes and mathematical models are used.

d. For high-conductivity materials (100~500W), specialized test schemes and mathematical models are used.

e. For adiabatic insulation materials (0.010~0.050W), specialized test schemes and mathematical models are used.

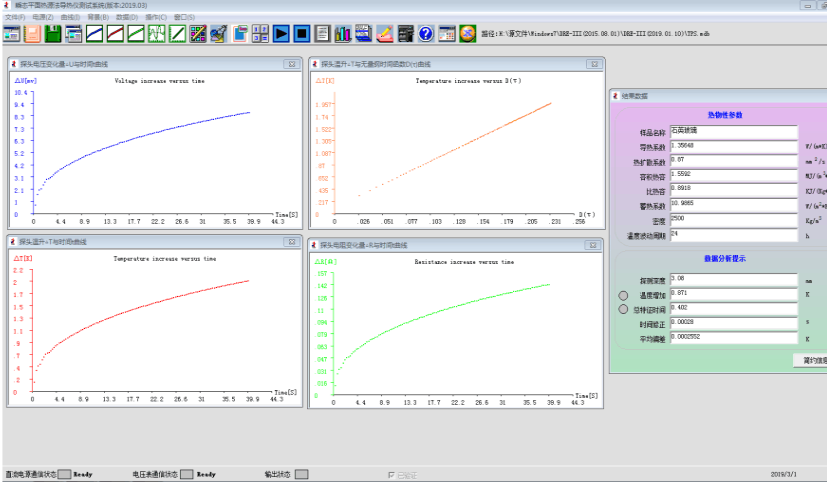

19. Software: Uses fully automatic testing software for rapid and accurate analysis of experimental process parameters and report output for samples.

20. Power supply: AC 220V±10%, 50/60 Hz, Overall power: <500w;

Software analysis diagram

Related Products

Inquiry Message

We will contact you within one working day. Please pay attention to your email.