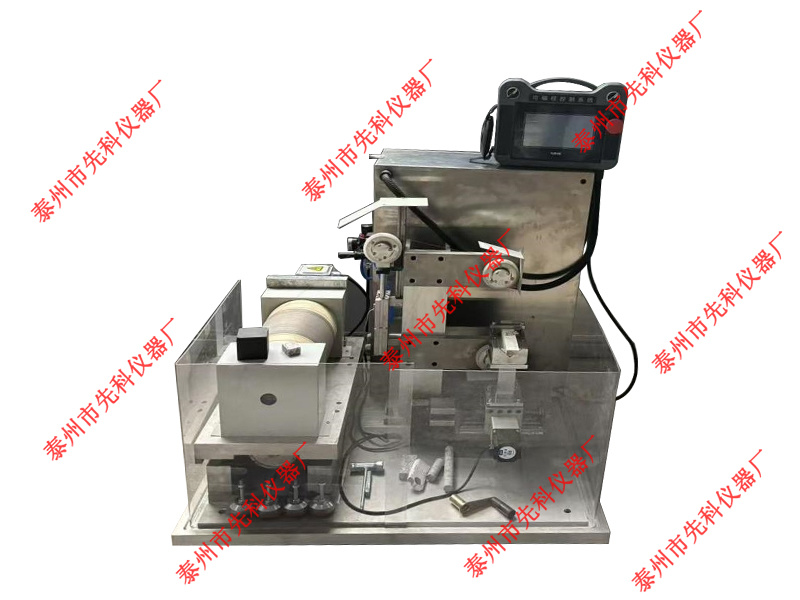

SCX-100 small diamond wire saw

Keywords:

Category:

Detailed description

Cutting size ≤φ100×100mm, cutting wire φ0.35~0.42mm, programmable and continuous cutting and slicing of hard and brittle materials

Product Introduction

The tabletop diamond wire cutting machine is a small tabletop diamond wire cutting equipment researched and manufactured by our company. It can be used for precise cutting of brittle materials such as ceramics, crystals, glass, metals, rocks, thermoelectric materials, infrared optical materials, composite materials, and biomedical materials, with a cutting size of up to 4". The SCX-100 tabletop diamond wire cutting machine is a single-wire reciprocating continuous diamond wire cutting machine. After setting the cutting program, the sample can be continuously cut. During the cutting process, the sample slowly moves towards the cutting wire, and the cut sample has high dimensional accuracy. The length of the cutting wire can be long (80m), extending the service life of a single loading, greatly improving cutting efficiency. The tensioning wheel adopts a pneumatic tensioning mode, with large tensioning force, and the tensioning force remains unchanged during the cutting process, maintaining the tension of the diamond wire. The SCX-100 tabletop diamond wire cutting machine can achieve high-efficiency and high-quality cutting, making it an ideal equipment for laboratories and production units.

Main Features

● Particularly suitable for cutting high-value, easily fractured crystals such as ZnO, BTO, YAG, BBO, etc., with a slicing success rate of over 99%.

● Equipped with a stepping motor for longitudinal and height adjustment, with an accuracy of ±10′, ensuring the accuracy of crystal orientation cutting.

● Uses an 80m long diamond wire for reciprocating cutting, with an adjustable wire speed of 0-2m/s.

● Metal wire and abrasive slurry can also be used for cutting.

● Uses stepping motor drive, automatic infeed cutting. The cutting speed can be adjusted according to different materials to improve cutting quality and extend the service life of the diamond wire.

Technical Parameters

1. Power supply interface: 220V three-pole plug

2. Total power: 250W

3. Main body composition: Aluminum alloy

4. Diamond wire length: ≤100m

5. Diamond wire diameter: ≤0.45mm

6. Diamond wire tensioning method: Pneumatic tensioning

7. Main shaft cutting rotation method: Reciprocating rotation

8. Main shaft speed: 2m/s adjustable

9. Cutting speed: 0.05~40mm/min

10. Return speed: 1~100mm/min

11. X-axis worktable effective stroke: ≤80mm

12. Y-axis worktable effective stroke: ≤80mm

13. X, Y-axis feed accuracy: 0.01mm

14. Cutting speed setting range: 0.05-40mm/min 15. Y-axis, X-axis drive motor: Precision stepping motor

16. Max distance between the two guide wheels: ≤160mm

17. Max workpiece diameter and length for cutting: Φ75mmX75mm

18. Control method: PLC programmer + 7-inch touch screen

19. Parameter display format: Digital

20. Safety control device: Winding reel over-travel, wire breakage automatic stop

Note: The equipment power supply is the domestic standard AC220V 50Hz power supply, and the actual power supply shall be subject to the parameters on the nameplate at the rear of the product.

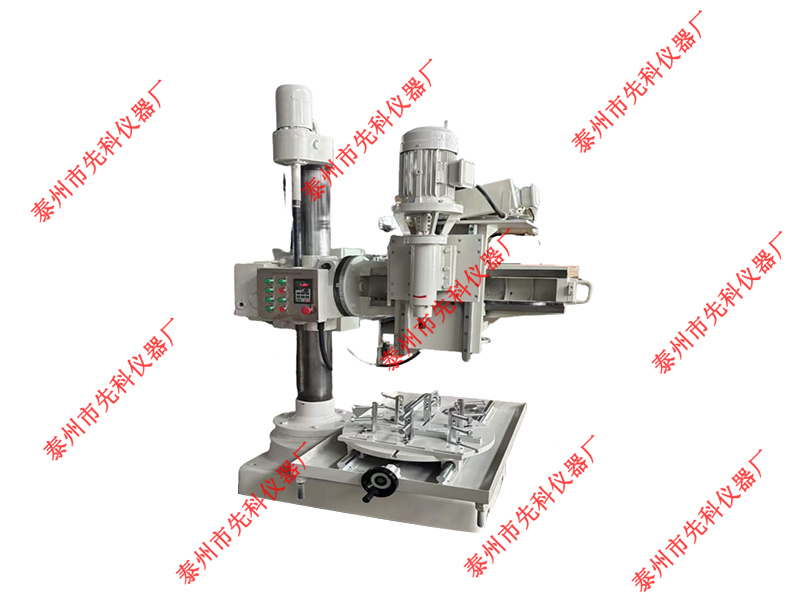

Related Products

Inquiry Message

We will contact you within one working day. Please pay attention to your email.