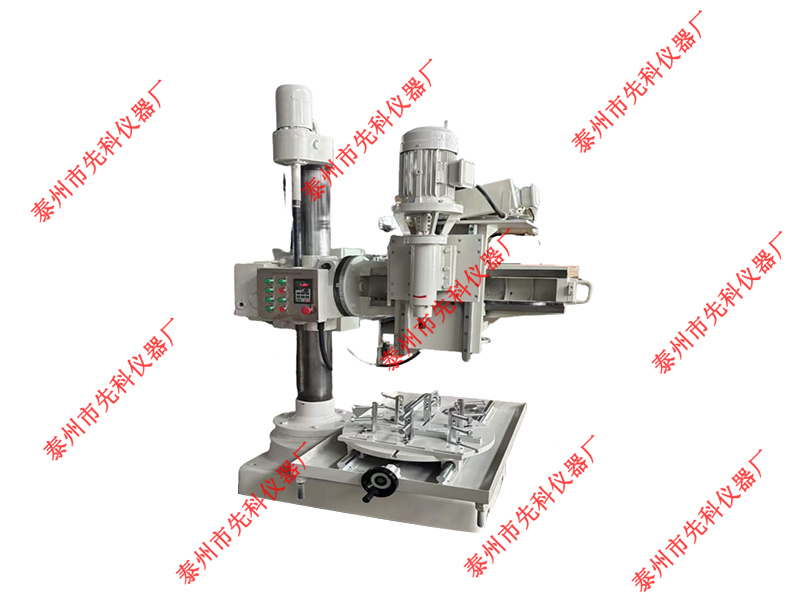

Core flow tester

Keywords:

Category:

Detailed description

A multifunctional core displacement physical simulation device can simulate reservoir temperature and pressure environments to conduct water drive, chemical drive, and gas drive enhanced oil recovery experiments; it collects and monitors experimental pressure, temperature, flow rate, oil-water saturation, and chemical agents, monitors the changing characteristics of residual oil inside the reservoir, evaluates the oil displacement effect and mechanism of different displacement methods, and optimizes injection-production well patterns, well spacing, and well types. The entire experimental process is automatically or semi-automatically controlled by a computer, with automated experimental operation and remote monitoring.

Main Specifications

1. Equipment Operating Environment Conditions

Temperature range: (5~30)℃

Humidity range: (40~60)% RH

2. Equipment Operating Power Conditions

Power distribution: Operating voltage 380V, 220V, frequency 50Hz, grounding required.

3. Design and Manufacturing Standards

(1) Basic Principles:

Following the principles of "advanced performance, reliable operation, convenient movement, economical operation, energy saving, environmental protection, and relevant requirements of national laws and regulations".

(2) Requirements of the Petroleum Engineering Technology Research Institute of Zhongyuan Oilfield Branch for the technical requirements, quality assurance, and after-sales service of the multifunctional core displacement physical simulation device.

(3) Safety Equipment and Facilities Requirements:

This instrument contains safety equipment and facilities and should have relevant certificates required by national laws and regulations on safety production permits and quality.

(4) The equipment design and manufacturing meet the requirements of Chinese laws and regulations, and can provide and handle various valid certificates; this system contains pressure vessels and has manufacturing licenses and qualified inspection reports issued by government-authorized authoritative departments, and the used metering instruments must complete the initial inspection and be qualified.

(5) All matching components contained in the system must be brand new, qualified, and genuine products, and products explicitly eliminated or inefficient and high-consumption products in China must not be used.

(6) The design, materials, equipment manufacturing process, quality control, and product inspection and acceptance of the multifunctional core displacement physical simulation device required by this technical proposal comply with current national standards and standards, as well as relevant enterprise standards. The standards and standards to be followed by the product mainly include, but are not limited to, the following ranges:

1) GB/T 29172-2012 "Core Analysis Methods"

2) GB/T 23804-2009 "General Technical Conditions for Conventional Core Analysis Instruments"

3) SY/T5358-2010 "Evaluation Method for Reservoir Sensitivity Flow Experiments"

4) GB/T 13966-1992 "Terminology of Analytical Instruments"

5) TSG R0004-2009 "Safety Technical Supervision Regulations for Stationary Pressure Vessels"

6) SY/T5542-2009 "Industry Analysis of Oil and Gas Reservoir Fluid Physical Properties"

7) JB/T4708-2000 "Welding Process Qualification for Steel Pressure Vessels"

8) JB4730-2005 "Non-destructive Testing of Pressure Vessels"

9) GB 4208 "Degrees of Protection Provided by Enclosures (IP Code)"

10) GB 50093 "Construction and Acceptance Specifications for Automation Instrument Engineering"

11) GB150-2011 "Steel Pressure Vessels"

12) GB/T 1227-2202 "Precision Pressure Gauges"

13) GB/T 15478-1995 "Performance Test Methods for Pressure Sensors"

If the relevant requirements of several standards and standards apply to the same situation, the most stringent clauses should be followed. The supplier is obligated to proactively provide the owner with other unlisted standards and standards related to this project. The supplier should provide a list of the standards and specifications used in this project and ensure that their versions are the latest versions (including revised versions).

Main Technical Parameters

The equipment can simulate reservoir temperature and pressure environments to conduct related experiments: enhanced oil recovery research, reservoir sensitivity evaluation, etc.; it collects and monitors experimental pressure, temperature, flow rate, oil-water saturation, and chemical agents, and the entire experimental process is automatically or semi-automatically controlled by a computer, with automated experimental operation and remote monitoring.

(1) Displacement pressure: ≤100MPa, accuracy: 0.1%FS;

(2) Confining pressure tracking pressure: ≤105MPa, accuracy: 0.1%FS, tracking response time: ≤0.1S, rate: 0.5MPa/S;

(3) Operating temperature: Room temperature -180℃, accuracy: ±0.5°C;

(4) Applicable core specifications: φ25×50-200mm, φ38×50-200mm;

(5) The double-cylinder pump is equipped with an automatic reversing system, flow rate range 0.001-50ml/min, pressure range 0-100MPa;

(6) Automatic oil-water metering range: 0-5000ml, accuracy: ±0.1ml;

(7) System wetted material: acid and alkali resistant HC276, other materials 316L;

(8) The constant temperature box meets the maximum operating temperature of 200℃ and forced air circulation, and the space size meets the needs of updated experiments, accuracy: ±0.5°C;

(9) Automatic outlet metering: Meets automatic oil-water metering at 180°C and 80MPa, accuracy: ≤0.1ml

Related Products

Inquiry Message

We will contact you within one working day. Please pay attention to your email.