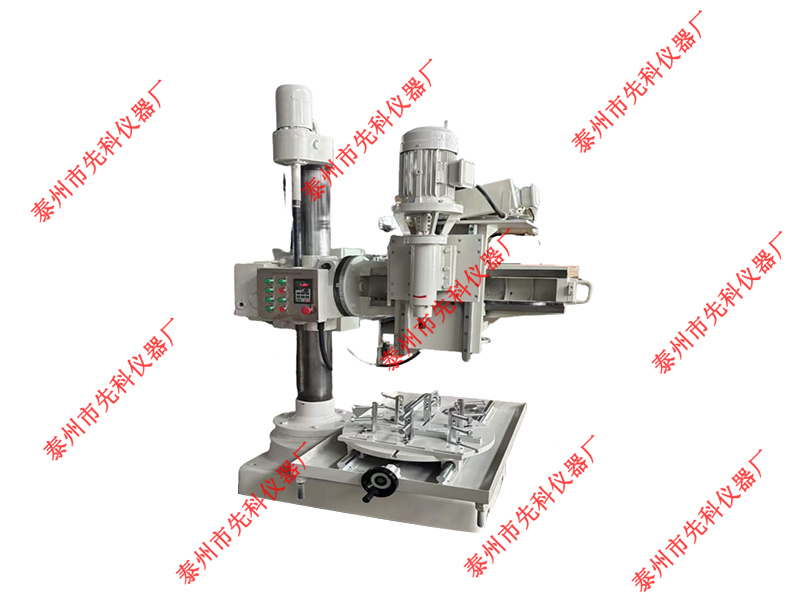

SCO-5630 diamond wire saw

This model offers optional slicing or shaping systems, a unidirectional wire feed structure, a diamond wire cutting control system, an infrared laser correction instrument, an auxiliary operating handwheel, optional water cooling or vacuum cleaner, a single-cylinder pneumatic fixture, and optional fully enclosed, semi-enclosed, and open sheet metal housings. Product Use Primarily used for slicing, it can also cut several regular simple shapes such as squares and circles. Applicable Scope Suitable for brittle materials with a Mohs hardness of no more than 7. The cutting height varies depending on the material; the higher the hardness, the lower the cutting height, and the slower the cutting speed. Equipment Features High-rigidity bed: The bed is made of traditional cast iron, which increases the stability of the machine tool compared to steel structures. Infrared laser correction instrument: Quickly corrects the placement of the workpiece, facilitating slicing and reducing waste. Unidirectional wire feed movement: Uses a ring-shaped wire saw for unidirectional high-speed movement, resulting in a cutting surface without obvious scratches, achieving a polishing effect through cutting, excellent chip removal, and stable wire tension. Accessories: Fixtures, according to specific processing technology characteristics, slicing uses a pneumatic cylinder fixture, which is simple, fast, and stable to operate. Simple operation: The slicing system uses a PLC touch screen operating system (self-developed), mainly for slicing, can cut regular simple shapes such as circles and squares, self-selected control, only needs to input cutting parameters; the shaping system is mainly used for cutting irregular shapes, using keyboard operation, supporting on-machine drawing or direct use of USB to import drawings for cutting.

Keywords:

Category:

Detailed description

This model offers optional slicing or shaping systems

• Unidirectional wire feeding structure

• Diamond wire cutting control system

• Infrared laser calibration instrument

• Auxiliary operating handwheel

• Optional water cooling or vacuum cleaner

• Single-cylinder pneumatic fixture

• Optional fully enclosed, semi-enclosed casing and open sheet metal

Product Use

Primarily used for slicing, it can also cut several regular simple shapes such as squares and circles.

Applicable Scope

Suitable for brittle materials with a Mohs hardness of no more than 7. The cutting height varies depending on the material; higher hardness results in lower cutting height and slower cutting speed.

Equipment Features

High-rigidity bed:

The bed is made of traditional cast iron, which increases the stability of the machine compared to steel structures.

Infrared laser calibration instrument:

Quickly calibrates the workpiece placement, facilitating slicing and reducing waste.

Unidirectional wire feeding movement:

Uses a circular wire saw for unidirectional, high-speed movement, resulting in a cutting surface without obvious scratches. It uses cutting instead of grinding, with excellent chip removal and stable wire tension. Accessories:

Fixtures: Depending on the specific processing technology, slicing uses a pneumatic cylinder fixture, which is simple, fast, and stable to operate.

Simple Operation:

The slicing system uses a PLC touch screen operating system (independently developed), mainly for slicing, capable of cutting regular simple shapes such as circles and squares. Self-selected control only requires inputting cutting parameters; the shaping system is mainly used for cutting irregular shapes, using keyboard operation, supporting on-machine drawing or direct cutting using USB imported drawings.

Related Products

Inquiry Message

We will contact you within one working day. Please pay attention to your email.