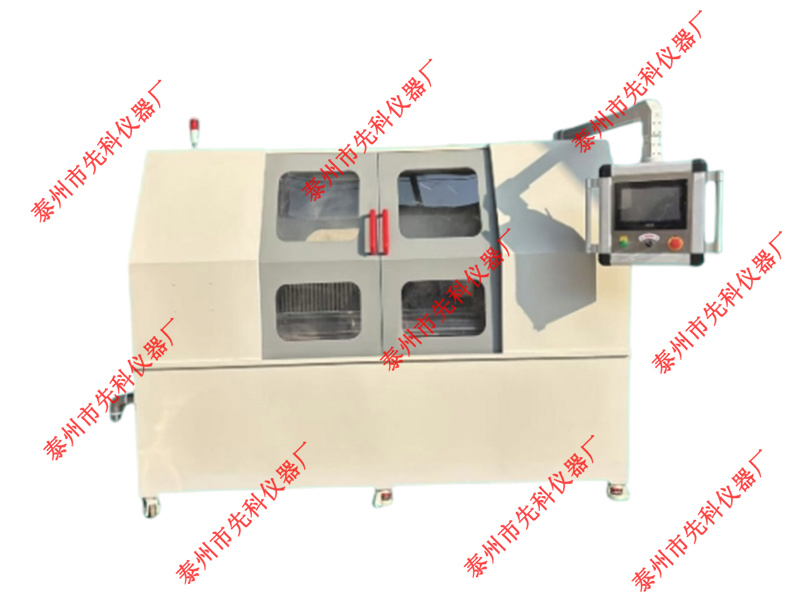

SCQ-1200P Program-controlled Automatic Core Sectioning System

Keywords:

Category:

Detailed description

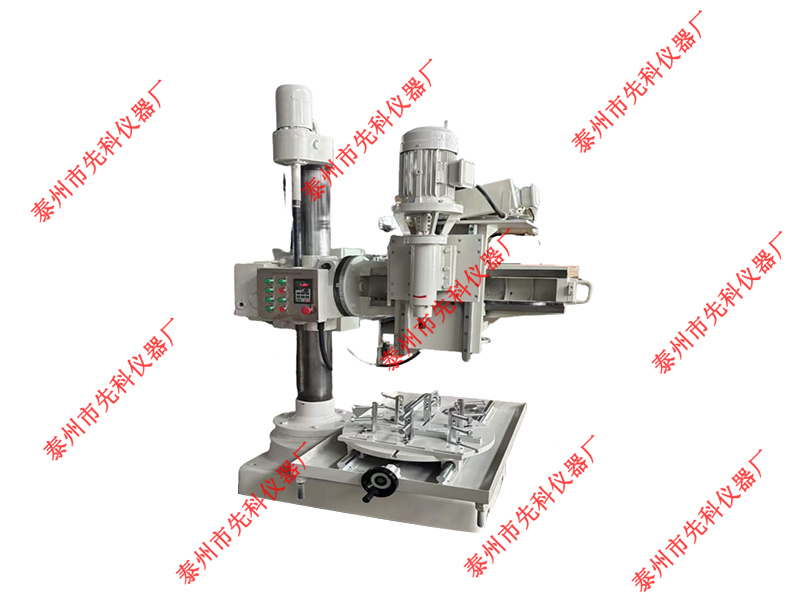

The SCQ-1200P core liquid nitrogen sectioning machine is one of our main products. The core liquid nitrogen sectioning machine is divided into six parts: core sectioning system, core workbench system, core fixture system, liquid nitrogen cooling system, chassis frame system, and automatic control system. Each system works in coordination under the dispatch of the control center and operates reliably; key operating data (such as sectioning speed, feed rate, sectioning length, etc.) are monitored and displayed in real time, and transmitted to the control center, and can display the simulated working status in real time; safety protection devices are complete and reliable (such as blade jamming alarm, abnormal operation alarm, double limit protection switch, leakage protection, emergency stop button, etc.); the overall structure of the equipment is reasonable, the noise is low, it is easy to operate and maintain, the performance is stable, and the technology is advanced; it meets international and domestic relevant safety, energy saving, and environmental protection requirements.

Main Technical Parameters

1. Core specifications: diameter 50~140mm, length 1200mm;

2. Sectioning blade: Ф460×Ф50×3×4×32mm; (blade outer diameter 460, inner diameter 50, 3*4*32 thickness*tooth thickness*tooth length)

3. Sectioning thickness: 15cm;

4. Double-knife spacing: 10mm, 15mm, 20mm;

5. Single-knife cutting: can be planed at ½, ⅓, etc.

6. Sectioning feed speed: 0~1000mm/min (speed automatically adjusts according to the size of the resistance);

7. Sectioning time: ≤5min;

8. Sectioning positioning accuracy: ≤±0.1mm;

9. Variable frequency main motor: imported servo control, maximum speed 2000r/min, power: 7kw;

10. Core workbench: lifting height 10~15cm, front and rear movement: 0~10cm, adjustable movement speed 0~1000mm/min;

11. Automatic intelligent control: key operating data are monitored and displayed in real time, simulating the working status; it has a safety warning function;

12. Cooling system: liquid nitrogen, air, water. Pipes and fittings use low-temperature resistant materials. The liquid nitrogen switch is sensitive and reliable; liquid nitrogen and air can be mixed to effectively cool the blade;

13. Core clamping mechanism: manual, pneumatic, replaceable;

14. Housing material: SUS304 stainless steel, with spray-painted anticorrosion treatment;

15. Working time: continuous;

16. Operating noise: less than 70 decibels, meeting the industrial enterprise noise hygiene standards.

Related Products

Inquiry Message

We will contact you within one working day. Please pay attention to your email.