What is a core drill? What should be paid attention to when using it?

Release Date:

2023-01-30

A core drilling machine is a mechanical equipment with a gasoline engine. Concrete core drilling machines are mainly used for two purposes. One is drilling on horizontal surfaces, suitable for installing road studs, bollards, bridge drilling procedures, and pile foundation drilling for integrated buildings.

What is a borehole sampler? What should be paid attention to when using it?

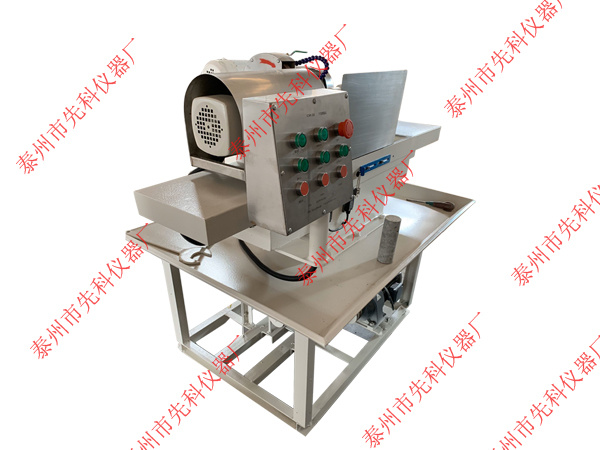

A borehole sampler is a mechanical device with a gasoline engine. Concrete borehole samplers are mainly used for two purposes. One is drilling holes on a horizontal plane, suitable for installing road studs, road markers, bridge drilling operations, and pile foundation drilling for integrated houses. It has been widely used in transportation engineering companies, China Railway Group, integrated housing companies, etc.; the second is coring, suitable for road coring testing, and has been widely used in testing centers across the country.

Borehole sampler operating instructions:

1 To ensure safe and normal operation, please read the operating instructions before use and familiarize yourself with the structure and operation methods of the drilling rig.

2 After moving the drilling rig to the required working position, swing the walking wheels backward 180 degrees, and use the operating handle to lift the walking wheels and steering wheel off the ground. Adjust the four adjusting bolts to firmly place the base at the working position. At this time, the datum plane is off the ground.

3 Wipe the drill column and lifting screws, and adjust the spindle position.

4 Connect the water pump to the water source and add water to the bucket to ensure that the water pump can supply water normally.

5 Install the upper drill bit.

6 Check and adjust all parts of the engine according to the requirements of the gasoline engine operating manual. If the engine is in normal condition, the engine can be started. Start drilling and coring.

Precautions for using a borehole sampler

1. When drilling, the drill bit should have low hand resistance and smooth cutting. The feed rate during the drilling process should be approximately 4-5m/min . When the drilling is nearing completion, due to changes in cutting force, the drilling will vibrate. At this time, the feed rate should be appropriately reduced. After the cutting is completed, the drill bit should be quickly lifted until the cutting edge is separated from the workpiece, and the drill bit should be turned off and the water source cut off.

2. Sufficient water cooling must be maintained throughout the drilling process

3. When quickly lifting the drill bit during and after drilling, do not stop, but stop the spindle rotation when the drill bit just leaves the work, and then lift the drill bit.

4 If the drill bit is found to be stuck during drilling, the drill bit should be quickly lifted a section, and then slowly drilled in. Do not damage the drill bit with hard drilling. 5 If the motor temperature exceeds during the drilling process 70 ℃, the machine should be temporarily stopped for cooling before use.

6. Move the switch knob, rotate the operating handle in the positive direction, and slowly bring the drill bit into contact with the concrete surface. After the drill bit enters the groove, pressure can be applied to the drill bit. 7. If the drill bit cannot drill during the drilling process, and the diamonds on the surface of the drill bit are not fully exposed, it is necessary to use abrasive materials (such as refractory bricks, grinding wheels, etc.) to cut the edges. When the diamonds on the surface of the drill bit are fully exposed, use the surface of the hand mold. Only after feeling the roughness can drilling be carried out.

Previous Page

Next Page

Related News