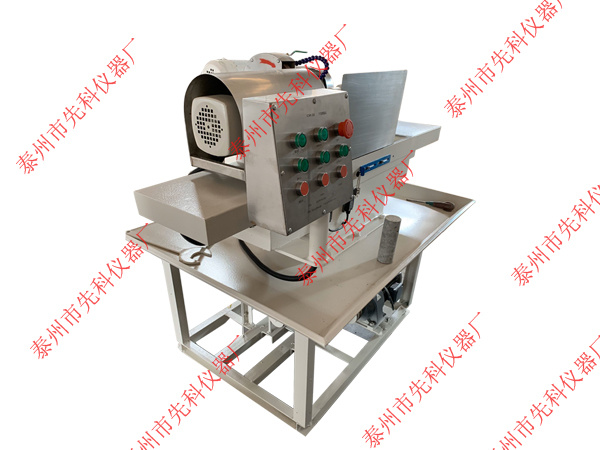

Introduction to the structure of an automatic wafer cutting and polishing machine. Collect it quickly!

Release Date:

2023-02-10

The core sample automatic cutting and grinding integrated machine is characterized in that: the water pump is connected to the power switch, and the power switch is set on the working handle of the electric saw. Furthermore, anti-slip strips are provided inside the curved groove.

What is the structure of an automatic core cutting and grinding machine? Let's find out.

The automatic core cutting and grinding machine includes a water storage base. A power saw is installed in the middle of one side of the water storage base. A slide seat is installed on the water storage base in front of the power saw. A slider is installed on the surface of the slide seat. A handwheel shaft is installed on the slider. The handwheel shaft is meshed with a rack. A rotating handwheel is installed at one end of the handwheel shaft. The rack is installed on the surface of the slide seat. A fixture seat with the same width as the slider is installed on the surface of the slider. A track groove is formed on the surface of the fixture seat. Several clamping plates are installed in the track groove. Arched grooves are formed on the corresponding sides of two adjacent clamping plates. A fixed abutment plate is installed on the side of the fixture seat where the power saw is located. An adjustable abutment plate is installed on the other side of the fixture seat corresponding to the fixed abutment plate. An adjusting screw for driving the clamping plate to clamp is installed on the adjustable abutment plate. A water pump is installed on the power saw. The water inlet pipe of the water pump is installed in the water storage base. The water outlet pipe of the water pump is installed on the side of the saw blade of the power saw.

The automatic core cutting and grinding machine is characterized in that: the water pump is connected to the power switch, and the power switch is installed on the working handle of the power saw. Further, anti-skid strips are installed in the arched grooves. In addition, a rotating rod is vertically installed on the surface of the rotating handwheel, and a filter screen is also installed at the bottom of the water inlet pipe. Further, a scale bar is installed on the surface of the slide seat, and the scale bar is set to "O" scale at the saw blade part of the chain saw, and is symmetrically set on both sides. Further, the length of the slide seat is at least 20 cm. In addition, the length of the slider is less than or equal to 6 cm.

What is the operating procedure of the automatic core cutting and grinding machine? Let's find out.

1. Turn on the power and water supply.

2. Select the appropriate fixture according to the core sample diameter, clamp the core sample, and turn it to the working position of the bottom plate control center, then tighten the fixture.

3. Loosen the upper and lower tightening handwheels, rotate the lifting handwheel, and stop when the grinding wheel end face is 1 mm away from the core sample end face. Then tighten the handle, open the water inlet valve, turn off the power switch, let the grinding wheel rotate, then rotate the handwheel counterclockwise, then rotate the micro handwheel clockwise, so that the grinding wheel head faces down. When the grinding wheel end face contacts the sample end face, swing the grinding head to grind until the sample end face is ground flat.

4. After grinding, turn off the power and water valve, and rotate the micro handwheel counterclockwise to its upper limit position.

5. Loosen the fixture tightening handle, remove the fixture and sample together, and reinstall it in reverse. Repeat steps 2, 3, and 4 to grind the other end face until the core sample end face meets the requirements.

6. After using the grinding machine, turn off the power and clean the machine.

Related News