Do you know what an automatic wafer cutting and polishing machine is? How to extend its lifespan?

Release Date:

2023-04-03

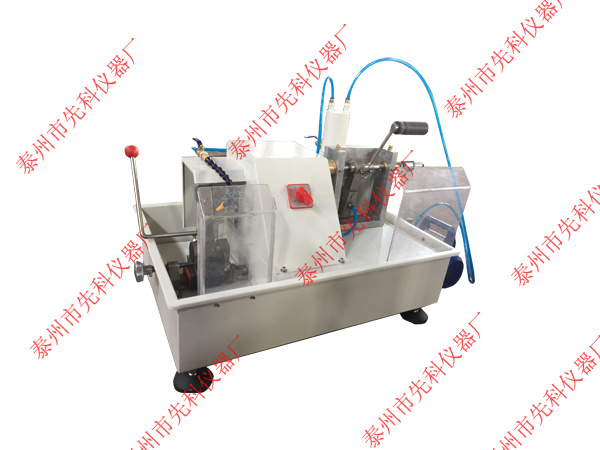

The automatic core sample cutting and polishing machine is a high-tech product that improves previous technologies by comprehensively applying computer technology, automatic control technology, automatic detection technology, and mechanical design and manufacturing. It is a typical mechatronics product with high technology density and a high degree of automation. Below, we will mainly introduce the important component systems of the automatic core sample cutting and polishing machine for your better understanding!

Automatic Core Sample Cutting and Grinding Machine It is a high-tech product that improves previous technologies by comprehensively applying computer technology, automatic control technology, automatic detection technology, and mechanical design and manufacturing. Automatic Core Sample Cutting and Grinding Machine It is a typical mechatronics integrated product with high technology density and high degree of automation. Below, we will mainly introduce the important component systems of the automatic core sample cutting and grinding machine for your better understanding!

1. Numerical Control System: The numerical control system is an important component of the rock cutting machine. Users can use various graphic input methods provided by the system to conveniently and flexibly establish and edit part graphics to achieve layout.

2. Pneumatic System: This system includes air supply pipes, valves, pressure reducers, pressure gauges, and solenoid valves. It is an automatic cutting technology developed based on rapid cutting technology.

3. Programming System: It is mainly a computer-aided system for part programming and nesting developed for CNC cutting machines.

4. Mechanical Operating System: The mechanical operating system consists of a beam, slide, deceleration mechanism, lifting mechanism, etc. It has strong anti-interference ability, especially at low speeds, the advantage is more prominent, which can make cutting jump from mechanical blanking to mechanical processing.

The above is Automatic Core Sample Cutting and Grinding Machine system composition information. Our automatic core sample cutting and grinding machine manufacturer's products are compact, fully sealed, low-noise, automatic material unloading, stable and reliable. For more information, please contact us.

Also, in order to ensure and extend the service life of the automatic core sample cutting and grinding machine, we usually need to do the following:

1. Try not to wait until the equipment is broken before relying on maintenance personnel to repair the equipment. Do a good job of maintenance on a regular basis.

2. The usage cycle frequency of the equipment must not be chaotic. The internal components of the equipment should be avoided from getting damp, otherwise it will cause the electronic components to deteriorate or be damaged.

3. After purchasing the equipment, try to use it within the warranty period, which can prepare for later batch processing.

4. Operators are required to use the equipment carefully according to the correct operating procedures;

5. Relevant personnel are required to carefully maintain the cutting machine.

6. If the enterprise task is not large, the equipment can be powered on regularly, idling for about 1 hour each time, using the heat generated during the operation of the equipment to remove and reduce the humidity inside the machine, ensuring the normal use of the equipment.

We are Automatic Core Sample Cutting and Grinding Machine manufacturer, and we have a detailed understanding of its characteristics and precautions. If you want to learn more about this, please contact us. We can introduce it to you from different aspects, so that you can have a better understanding of this aspect. The automatic core sample cutting and grinding machine is a very good product, making our work more efficient and easier.

Related News